Product Description

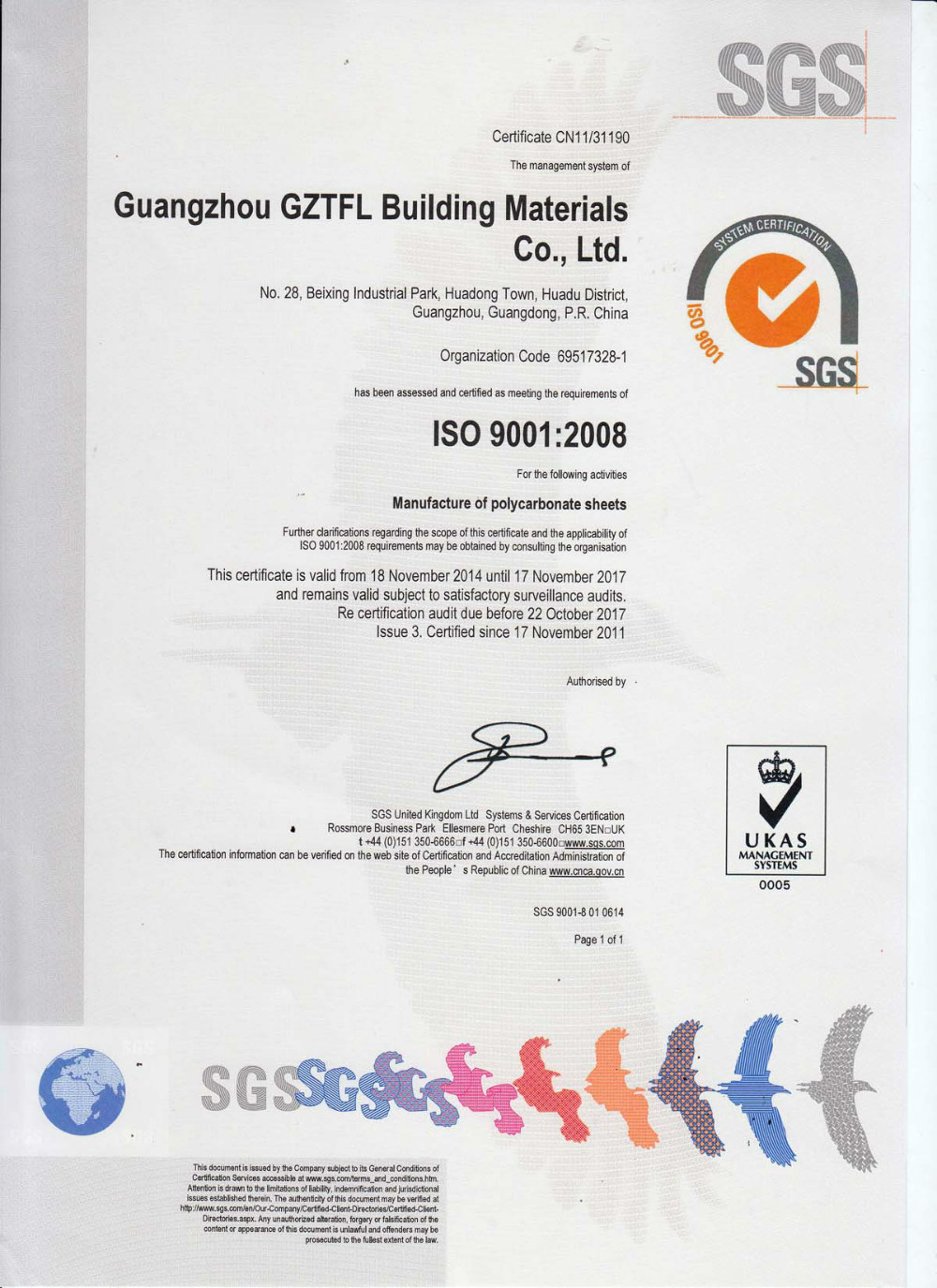

SGS ISO Approve Ten Years Guarantee UV Protection Colored Solid/Hollow Polycarbonate Roofing Sheet Manufacturers

Material of polycarbonate sheet: From Germany Bayer,GE lexan

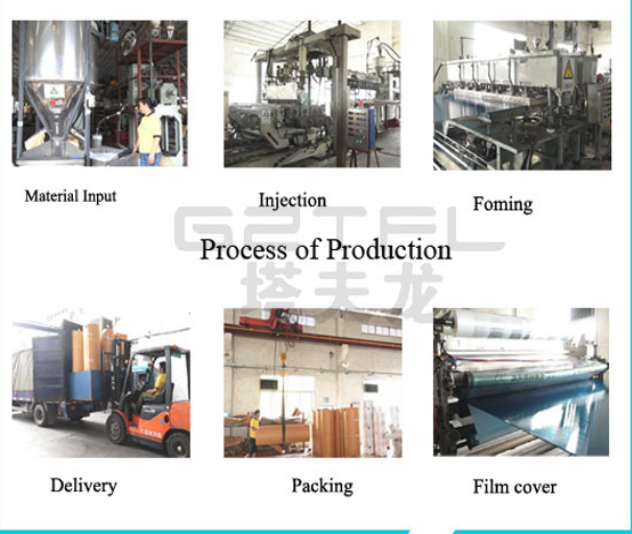

Production line: 6 line

Workshop requirement: ISO9001:2008

Quality:100% virgin Bayer material for polycarbonate.

UV coating

10 years warranty

approved by ISO9001: 2008

delivery time 7-10 days

1. Specifications:

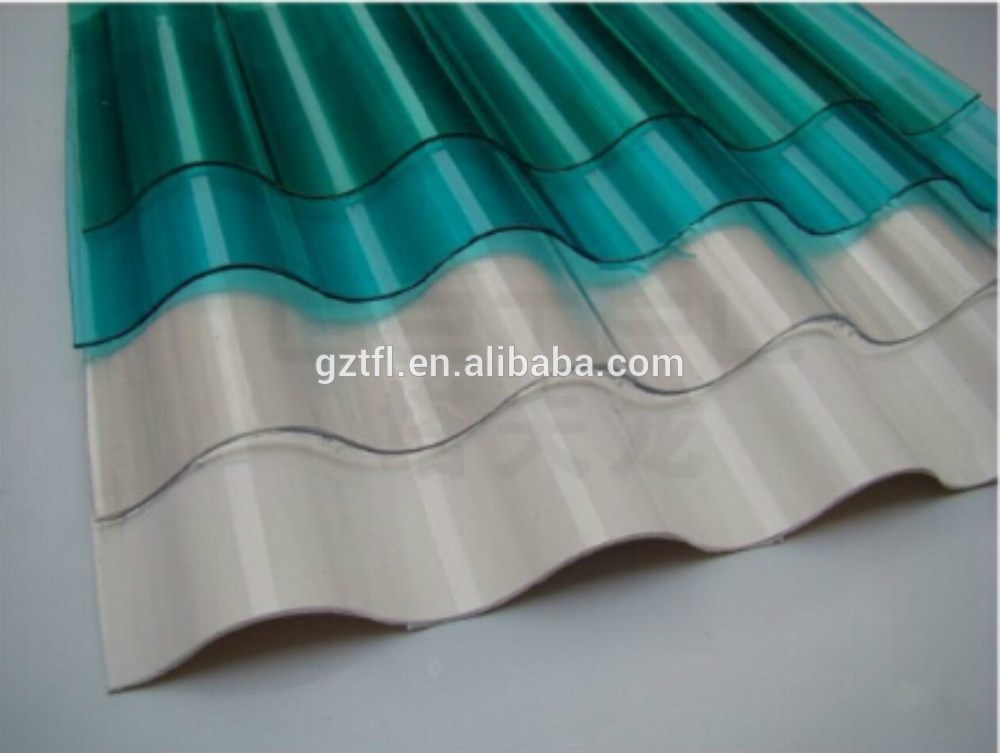

1) Thickness:polycarbonate Solid Sheet: 1.2mm-12mm

2) Thickness: polycarbonate Hollow Sheet: 4mm-16mm

2) Max Width: 2,100mm

3)Length:can be cut as your requirement

4) Colors: clear, lake blue, green, blue, opal, bronze, gray, Orange ,red, Limom .

(Other color can be ordered according to your request)

2. Features:

1) High light transmission: over 88%

2) Excellent impact resistance: 80 times of same thick glass. 3) Weather and UV resistant-properties retained for years.: Temperature resistance range is -40°C ~ +120°C, with an ultraviolet coextruded film on the sheet surface. It can prevent the resin fatigue or yellowing caused by the ultraviolet. 4) Light weight: only 1/12 of the weight of glass of the same thickness. It can be easily cold bent as well as thermal shaping. 5) Flame resistance: High fire performance rating is class B1. 6) Sound and heat insulation: Superb sound insulation for freeway barrier and super thermal insulation save energy. 7) An engineering plastic of excellent integration capability. It has outstanding physical, mechanical, electrical and heat capabilities.

Technical Features lexan polycarbonate sheet:

| 1) Impact strength: | 850J/m. About 200-350 times of common glass. |

| 2) Light weight: | About 1/2 times of glass of the same thickness. |

| 3) Light transmission: | 80%-92% for different thickness of clear color |

| 4) Specific gravity: | 1.2 g/cm3 |

| 5) Coefficient of thermal expansion: | 0.065 mm/m° C |

| 6) Temperature range: | -40° Cto 120° C |

| 7) Heat conductivity: | 2.3-3.9 W/m2 º |

| 8) Tensile strength: | >=60N/mm2 |

| 9) Flexural strength: | 100N/mm2 |

| 10) Heat deflection temperature | 140 ° C |

| 11) Modulus of elasticity: | 2, 400mPa |

| 12) Tensile street at break: | >=65mPa |

| 13) Elongation at break: | >100% |

| 14) Specific heat: | 1.16J/kgk |

| 15) Soundproof index: | 4mm-27dB,10mm-33dB |

Applications of lexan polycarbonate sheet:

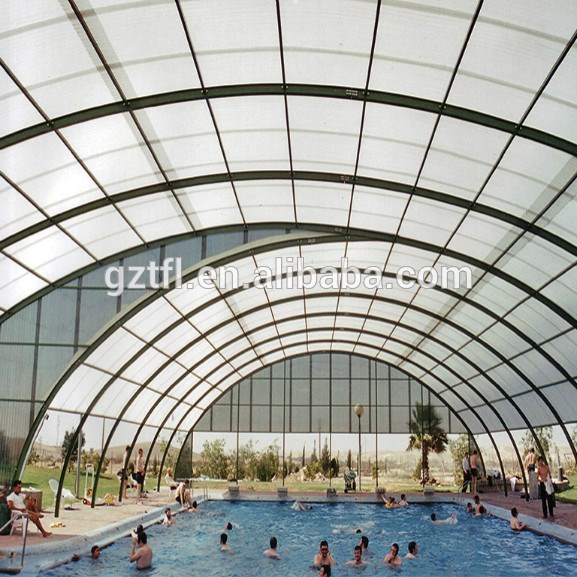

| 1), Roofing skylight for office building, department store, hotel, stadium, school, hospital. |

| 2), Soundproof shields on express ways. |

| 3), LED diffused, Advertising lamp boxes, sign board.Telepohne booths. |

| 4), Anti-riot shield, bullet resistant material, Bank ATMs. |

| 5), Agricultural greenhouses, zoos, botanical gardens. |

| 6), Swimming Pools roofing/cover/sheet |

| 7), Lighting for corridors, balcony, passages and subway entries, walkways. |

| 8), Walls, roofs,windows,screens,shower enclosure and other indoor decoration material. |

| 9), Instrument and machine windscreen |

Packing: With two side PE film packing to protect the sheet.

Company Information

Guangzhou Gztfl Building Materials Co.,Ltd. located in Guangzhou, which is a leading professional polycarbonate manufacturer have more than 12 years experience.

Our company only use 100% virgin Bayer Material from Germany. Approved by ISO, SGS, ROHS, ect; We have received high reputation with our quality products around theworld, Most of our cusotmer cooperation with us more than 10 years, so our output every month very big, about 50 containers average.

We’ll try our best to support our customers’ business and hope to establish long-term relationship with you in the near future

FAQ

1.Whats kind of a company we are ?

We are a manufacturer located Guangzhou, China .We have gained good reputation among our customers for our professional,warm and thoughtful service, Because we know that a long terms business based on the quality control ,delivery time etc.

2.Does your company is a factory or trade company ?

We have a factory ourself , we are on this business for fmore than 12 years in China.

3.Whats the quality assurance we provided and how do we control quality ?

1). Established a procedure to check products at all stages of the manufacturing process - raw materials, in process materials,validated or tested materials, finished goods, etc. Besides, we have also developed a procedure which identifies the inspection and test status of all items at all stages of the manufacturing

process.

2). 100% inspection in assembly lines. All controls, inspections, equipment, fixtures, total production resources and skills are inspected to ensure they consistently achieve the required quality levels

4.Your company can product how many different kinds of PC sheet ?

Our company now have following several products: Glittering Polycarbonate Sheet,Multi-wall Structure Polycarbonate Sheet,Greenhouse Polycarbonate Sheet, General Polycarbonate Solid Sheet,Advertising Polycarbonate Sheet, PolycarbonateEmbossed Sheet, Polycarbonate Frosted Sheet, Soundproof Polycarbonate Sheet, Greenhouse Polycarbonate Sheet etc.

5.What are polycarbonate sheets?

Polycarbonate sheets are a transparent, synthetic product. Because of its exceptional impact, weather and

temperature resistance, it provides solutions where other synthetics fail. With UV protection, sound insulation,light transmission is 88%.

6.Can I install polycarbonate sheets myself?

Polycarbonate sheets are particularly user friendly and very light, so that fewer cross bars are needed. This

makes the supporting structure more straightforward and cheaper.

7. Do the sheets discolor overtime?

Because of its transparent UV protective layer polycarbonate sheets do not discolour and most polycarbonate sheets come with a 10-year guarantee but they can last even longer than that!